Dr. Jin-yang ZHU is an Associate Professor in the National Center for Materials Service Safety at the University of Science & Technology Beijing. His research areas include CO2/H2S corrosion, hydrogen-induced damage, multi-phase flow corrosion, corrosion monitoring, and atmospheric corrosion, etc.

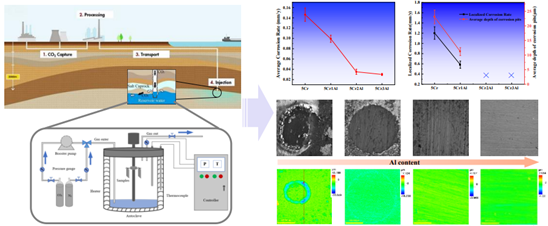

- Project 1:“National Natural Science Foundation of China”, “The influence of al addition on the localized corrosion resistance of low-cr steel under CO2-O2 coexisting environment and its mechanism”, total fund 300000 RMB, 2022-2024

- Project 2:“Basic technical projects from xxx”, total fund 1200000 RMB, 2023-2026

- Project 3:“Basic technical projects from xxx”, total fund 1620000 RMB, 2024-2025

In light of the service damage risks encountered by energy equipment materials in the oil, gas, and chemical industries, our research focus on corrosion and fatigue damage under complex and severe operating conditions. These include supercritical CO2 corrosion in CCUS applications, hydrogen-induced damage in high-pressure hydrogen environments, and H2S/CO2 corrosion in oil and gas pipelines. Utilizing self-developed HTHP CO2/H2S reactors, supercritical CO2 corrosion slow tensile testing devices, HTHP in-situ electrochemical testing devices, and gas phase/electrochemical hydrogen permeation testing devices, we have conducted an in-depth investigation into the corrosion and hydrogen damage mechanisms of carbon steel, stainless steel, and various CRAs under the above conditions. Consequently, we have developed material selection guidelines for typical working conditions and introduced a range of cost-effective corrosion-resistant materials, such as low-Cr steels and Fe-Cr-Al low alloy steels. Furthermore, to address the requirements for on-site corrosion evaluation and the application of big data technology, we have independently developed various on-site safety monitoring sensor systems, including high-resolution localized corrosion monitoring probes, in-situ hydrogen permeation monitoring probes, and array ultrasonic wall thickness monitoring probes, all of which have been successfully implemented in the field.

Related publications:J Alloy Compd, 1010 (2025) 177217; Surf & Interfaces, 56 (2025) 105709; Process Saf Environ, 192 (2024) 738-749; Electrochim Acta, 478 (2024) 143818; J Mater Res Technol, 15 (2021) 5078-5094; Oxid Met, 94 (2020) 265-281; J Mater Res Technol, 9 (2020) 8104-8116; Appl Surf Sci, 511 (2020) 145624; Rsc Adv, 9 (2019) 38597-38603; Corros Sci, 111 (2016) 711-719; Corros Sci, 111 (2016) 391-403; Appl Surf Sci, 379 (2016) 39-46; Corros, 71 (2015) 854-864; Corros Sci, 93 (2015) 336-340.

1. Fubing Liu, Qinwang Tang, Yunan Zhang, Jinyang Zhu*. Effect of Al content on mechanical properties and corrosion performance of novel Fe-Cr-Al alloy steels in a CO2-O2 coexistence environment. J Alloy Compd, 2025, 1010: 177217;

2. Zhihao Qu, Xue Jiang, Xiaoxiao Zou, Xiaoqi Yue, Yunying Xing, Jinyang Zhu*, Lei Zhang. An active learning framework assisted development of corrosion risk assessment strategies for offshore pipelines. Process Saf Environ, 2024, 192: 738-749

3. Jinyang Zhu*, Binxia Ma, Dapeng Li, Yunan Zhang, Lining Xu. Role of bicarbonate in CO2 corrosion of carbon steel. Electrochim Acta, 2024, 478: 143818

4. Jinyang Zhu, Lining Xu, Zhicao Feng, Gerald Frankel, Minxu Lu, Wei Chang. Galvanic corrosion of a welded joint in 3Cr low alloy pipeline steel. Corros Sci, 2016, 111: 391-403

5. Jinyang Zhu, Lining Xu, Minxu Lu, Lei Zhang, Wei Chang, Lihua Hu. Essential criterion for evaluating the corrosion resistance of 3Cr steel in CO2 environments: prepassivation. Corros Sci, 2015, 93: 336-340

Phone:+86-10-62333510

Email:ncms@ustb.edu.cn

Address: 12 Kunlun Road,Changping District, Beijing, 100026